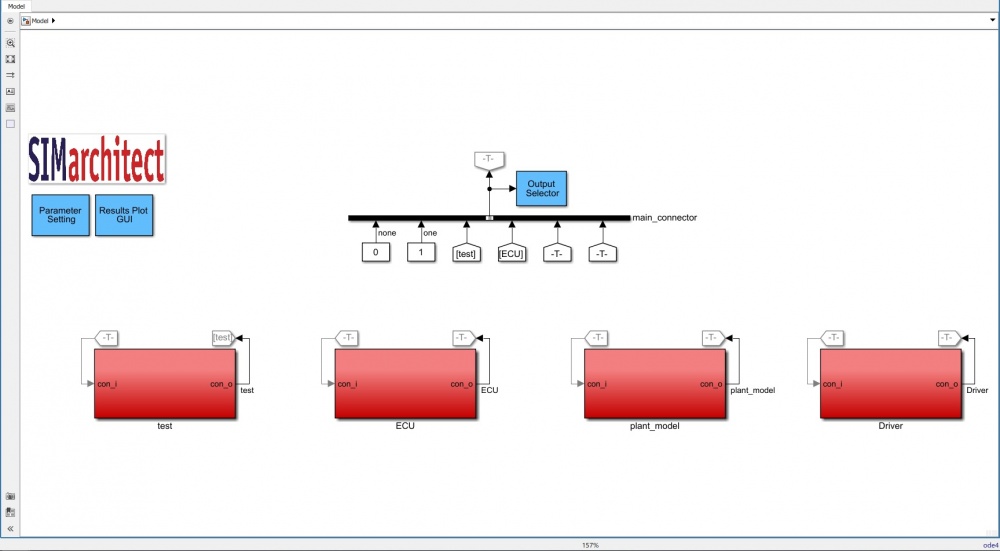

Parallel Hybrid Vehicle Simulation

This page provides the steps on how to model a parallel hybrid vehicle, it has been documented in such a way that first time user can recreate the simulation from the beginning.

The reference result of this particular vehicle has been uploaded so that the user can compare their own simulation.

To learn more about how to create a simple model, go to ADVANCE Tutorial

Contents

Creating the simulation

All the component modules which are going to be used in this example can be downloaded from ADVANCE Library.

The model is split into four different group modules. Those are:

- Test scenarios (Driving cycle and Environment condition)

- ECU

- Plant model (Parallel Hybrid vehicle powertrain component)

- Driver (Vehicle driver model)

First, insert three empty_area components from TNO ADVANCE general library to make ECU, Plant model and Driver group modules and rename them accordingly.

Delete the in and out ports as it is shown in the red box, since those ports will not be used.

The selection of input for each module has to be inserted according to the order otherwise the simulation result will be inaccurate.

Do not forget to select the location of the parameter files inside Parameter Setting'.

Test Scenarios

Insert the test scenarios module from the library to ADVANCE. Use the parameter_main m.file to load the desired driving cycle and adjust the environment condition.

The driving cycle for this example uses WHVC (World Harmonized Vehicle Cycle) as the drive cycle input.

ECU

Insert the ECU module to the first empty_area and notice that the from block is automatically connected to the bus connector of the output port of this empty_area.

The input signals to the ECU modules are:

| Subsystem | Input signal | Signal label | Retrieved from |

|---|---|---|---|

| Driver | Accelerator pedal position | Drv_AccPedl_Rt | Vehicle driver manual sensor |

| Brake pedal position | Drv_BrkPedl_Rt | ||

| Drive cycle reference speed | Drivecycle_RefSpeed_mps | ||

| Clutch pedal position | Drv_CluPedl_Rt | ||

| Requested gear number | Drv_nrGearReq | ||

| Plant model | Actual engine speed | Eng_nAct_radps | Engine sensor |

| Crankshaft torque | Eng_tqCrkSftAct_Nm | ||

| Indicated torque | Eng_tqindAct_Nm | ||

| Engine oil temperature | Eng_tOilAct_K | ||

| Battery output current | Batt_iAct_A | Battery sensor | |

| Battery output voltage | Batt_uAct_V | ||

| State of charge | Batt_socAct_Rt | ||

| Battery temperature | Batt_tAct_K | ||

| Clutch disengaged or not | Clu_flgConnected_B | Clutch sensor | |

| Electric machine output torque | ElecMac_tqAct_Nm | Electric machine sensor | |

| Electric machine output speed | ElecMac_nAct_radps | ||

| Electric machine output current | ElecMac_iAct_A | ||

| Electric machine output temperature | ElecMac_tAct_K | ||

| Transmission output speed | Transm_nOutAct_radps | Transmission sensor | |

| Transmission gear number | Transm_nrGearAct | ||

| Clutch lock | Transm_flgConnected_B | ||

| Transmission input speed | Transm_nInAct_radps | ||

| Vehicle velocity | Chassis_vVehAct_mps | Chassis sensor | |

| Wheel speed | Chassis_nWheelAct_radps | ||

| Vehicle mass | Chassis_massVehAct_kg | ||

| Road slope | Chassis_slopeRoad_kg | ||

| Auxiliary system output current | Aux_iAct_A | Electrical auxiliary sensor |

Plant model

Insert the parallel hybrid vehicle powertrain to the second empty_area.

The components of parallel hybrid vehicle powertrain are:

- Internal Combustion Engine

- Clutch

- Mechanical connection

- Transmission

- Final gear

- Chassis

- Battery

- Electric machine

- Electrical auxiliary system

The input signals for each component modules are:

| Module | Input signal | Signal label | Retrieved from |

|---|---|---|---|

| Internal combustion engine | Requested engine speed | Eng_nReq_radps | ECU cmd |

| Switch Speed / torque control | Eng_flgReqSwitch_B | ||

| Requested engine torque | Eng_tqReq_Nm | ||

| Exhaust brake ON / OFF | Eng_flgExhaustBrake_B | ||

| Engine ON / OFF | Eng_flgonoff_B | ||

| Starter motor ON / OFF | Eng_strtReq_B | ||

| Fuel cut off | Eng_flgFuelCut_B | ||

| Engine rotational speed | phys_speed_radps | Clutch mechanical fb output | |

| Clutch | Requested clutch pedal position | Clu_ratReq_B | ECU cmd |

| Clutch torque input | phys_torque_Nm | ICE mechanical output | |

| Clutch inertia input | phys_inertia_kgm2 | ||

| Clutch rotational speed input | phys_speed_radps | Mechanical connection mechanical fb output1 | |

| Mechanical Connection | Mechanical connection torque input 1 | phys_torque_Nm | Clutch mechanical output |

| Mechanical connection inertia input 1 | phys_inertia_kgm2 | ||

| Mechanical connection torque input 2 | phys_torque_Nm | Electric machine mechanical output | |

| Mechanical connection inertia input 2 | phys_inertia_kgm2 | ||

| Mechanical connection feedback input | phys_speed_radps | Transmission mechanical fb output | |

| Transmission | Requested gear number | Transm_nrGearReq | ECU cmd |

| Transmission torque input | phys_torque_Nm | Mechanical connection mechanical output | |

| Transmission inertia input | phys_inertia_kgm2 | ||

| Transmission rotational speed input | phys_speed_radps | Final gear mechanical fb output | |

| Final gear | Final gear torque input | phys_torque_Nm | Transmission mechanical output |

| Final gear inertia input | phys_inertia_kgm2 | ||

| Final gear rotational speed input | phys_speed_radps | Chassis mechanical fb output | |

| Chassis | Requested chassis brake torque | Chassis_tqBrake_Nm | ECU cmd |

| Chassis torque input | phys_torque_Nm | Final gear mechanical output | |

| Chassis inertia input | phys_inertia_kgm2 | ||

| Drivecycle slope | Chassis_slopeRoad_Rad | Test scenarios | |

| Battery | Battery current input | battery | Plant model bus connector |

| Battery Actual cooling flow | Batt_flowActCooling_kgps | ECU cmd | |

| Electric machine | Requested electric machine speed | ElecMac_nReq_radps | ECU cmd |

| Switch speed / torque control | ElecMac_flgReqSwitch_B | ||

| Requested electric machine torque | ElecMac_tqReq_Nm | ||

| Electric machine actual cooling flow | ElecMac_flowActCooling_kgps | ||

| Electric machine voltage input | phys_voltage_V | Battery electrical output | |

| Electric machine rotational speed input | phys_speed_radps | Mechanical connection mechanical join output 2 | |

| Electrical auxiliary system | Requested power | Aux_pwrElecReq_W | ECU cmd |

| Voltage input | phys_voltage_V | Battery electrical output |

Battery current input (green box) is a summation of current from Electric machine module and Electrical auxiliary system.

Driver

Insert the chosen vehicle driver to the third empty_area, vehicle driver manual is going to be used for this example.

The input signals for the driver module are:

| Subsystem | Input signal | Signal label | Retrieved from |

|---|---|---|---|

| Plant model | Actual vehicle velocity | Chassis_vVehAct_mps | Chassis sensor |

| Transmission input speed | Transm_nInAct_radps | Transmission sensor | |

| Transmission actual gear number | Transm_nrGearAct | ||

| Clutch disengaged or not | Clu_flgConnected_B | Clutch module | |

| Driver | Accelerator pedal rate | Drv_AccPedl_Rt | Driver module |

| Drive cycle | Drive cycle time and speed | drivecycle_time_speed | Test scenario module |

Simulation Settings

There are several settings which has to be changed on simulink, those are:

| Settings | Value |

|---|---|

| Time | 1800 [s] |

| Fixed - step size | 0.01 |

| Solver type | ode3 (Bogacki - shampine) |

The sequence of running the simulation:

- First, run parameter_main m.file

- Second, choose the desired output results in the Output Selector block

- Third, run ADVANCE in Simulink

- Fourth, plot the results using Results Plot GUI block

The output from each individual module can be plotted using the Results Plot GUI.

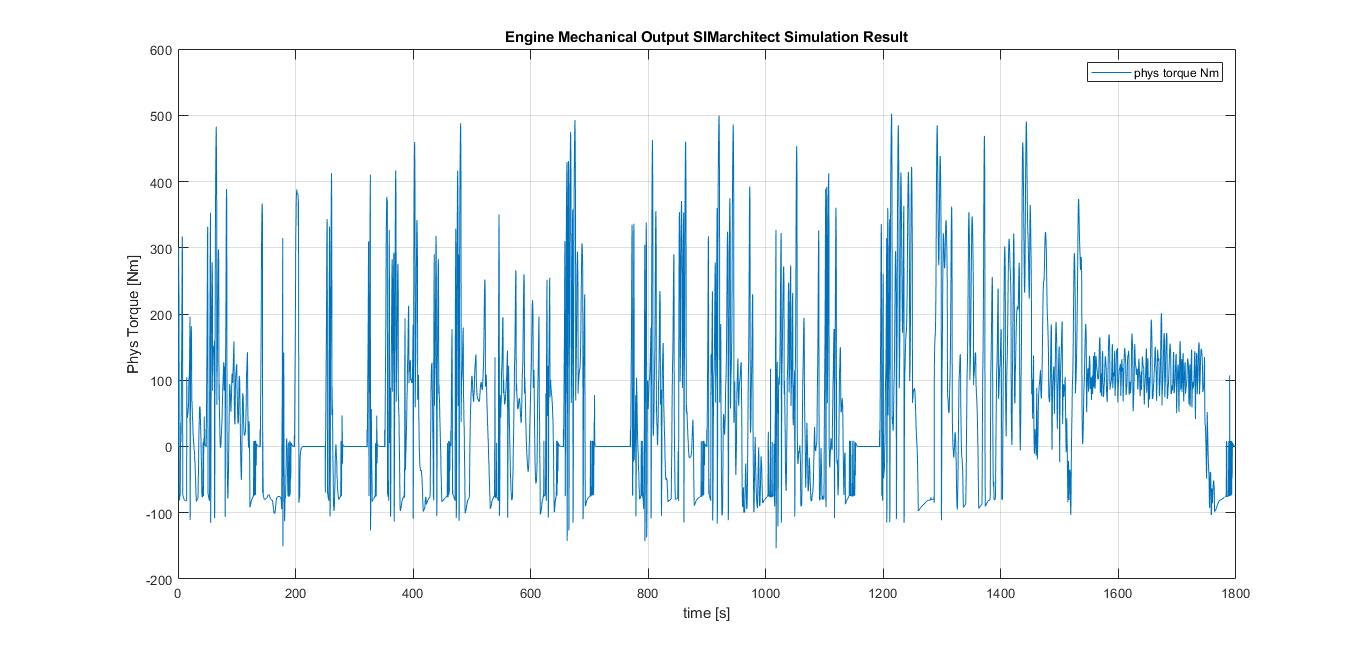

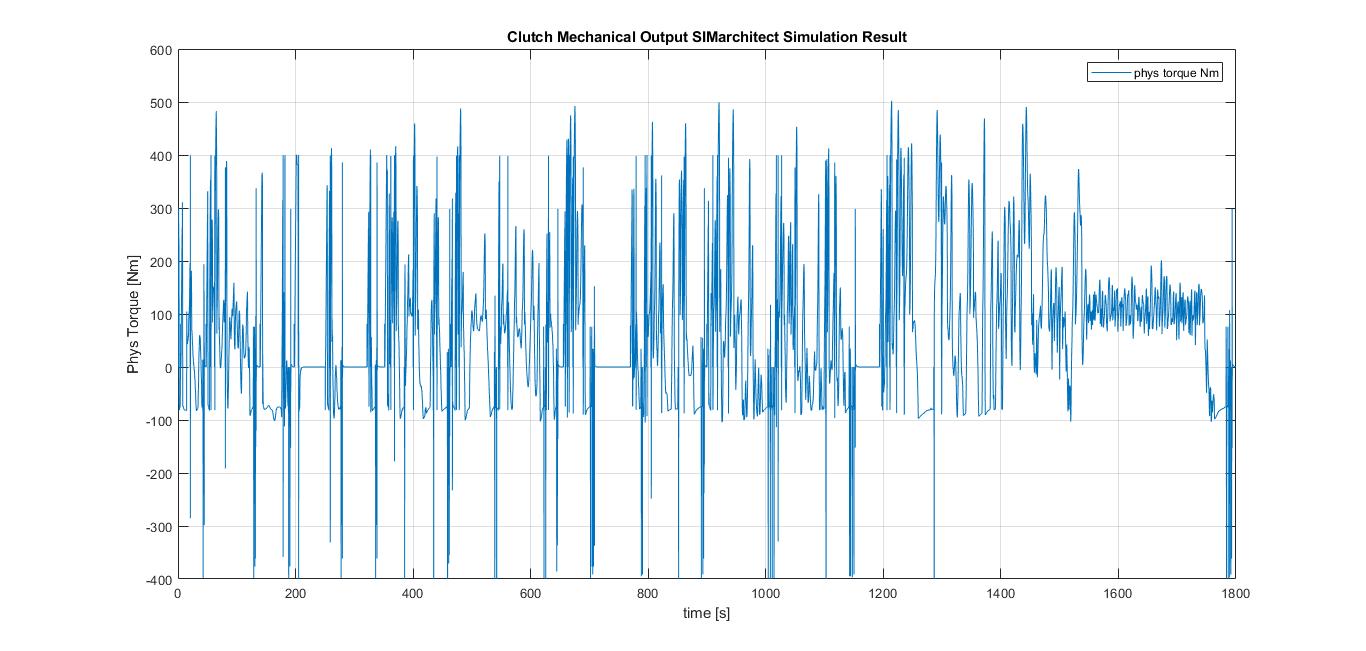

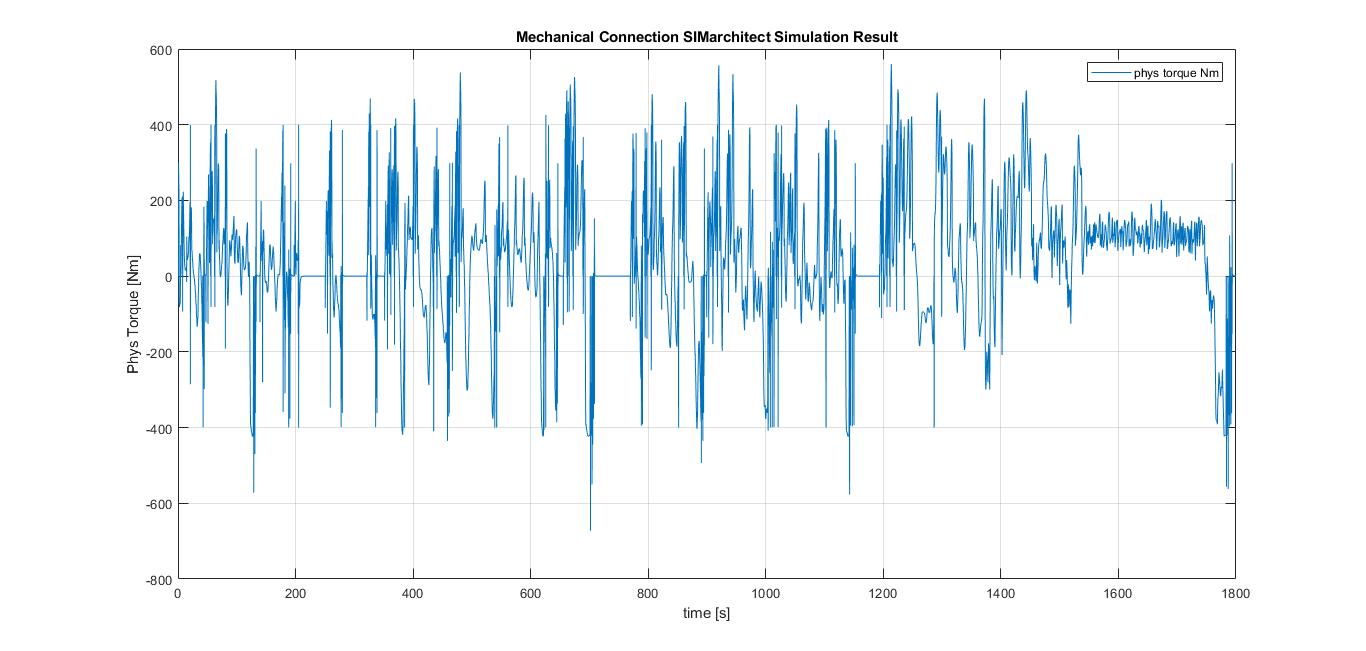

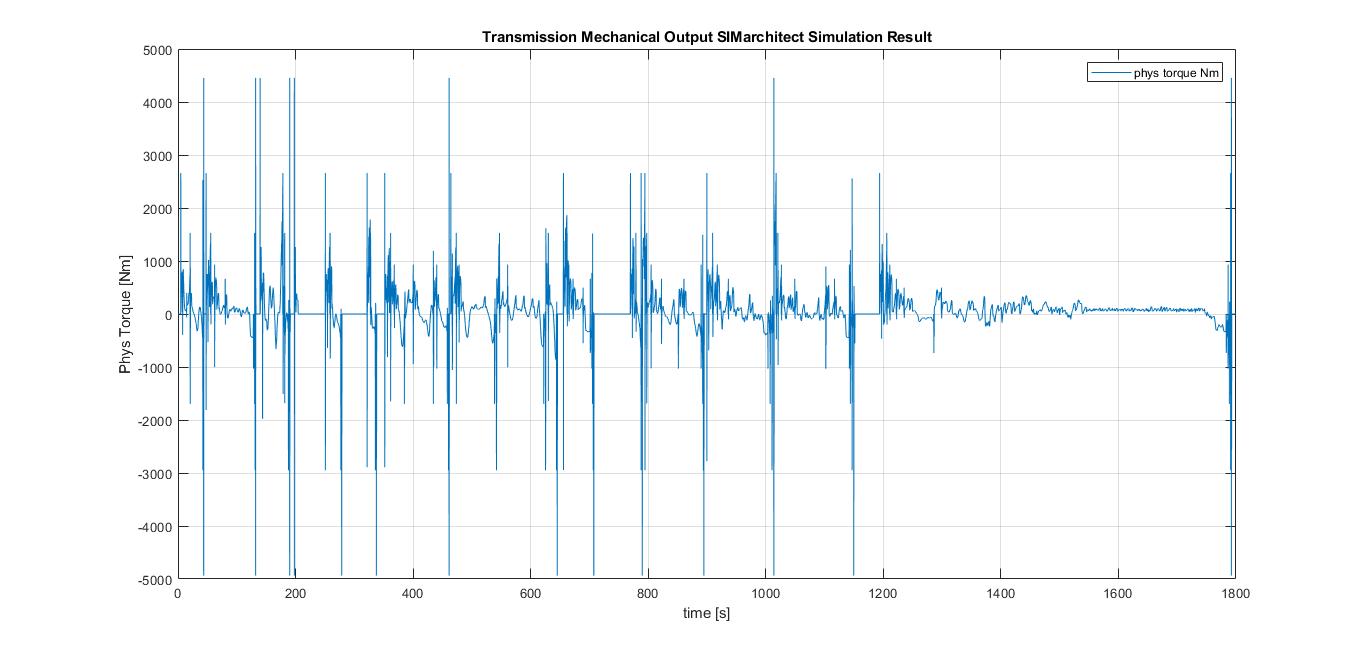

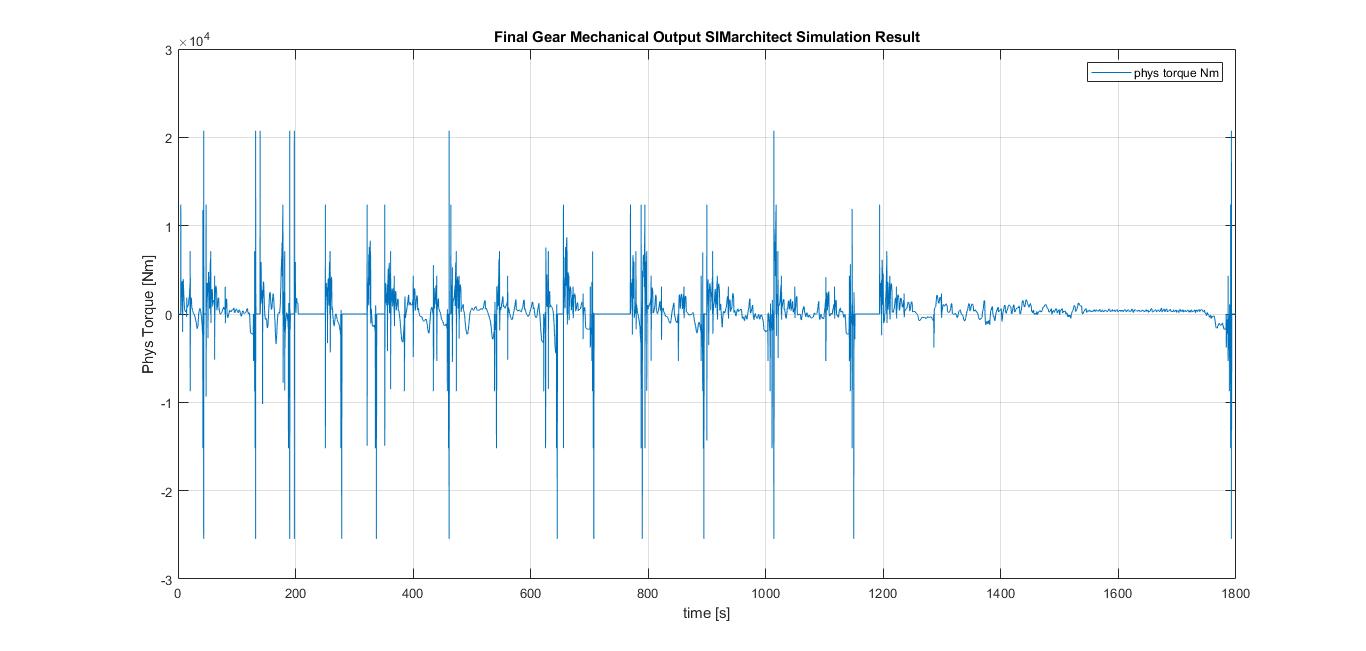

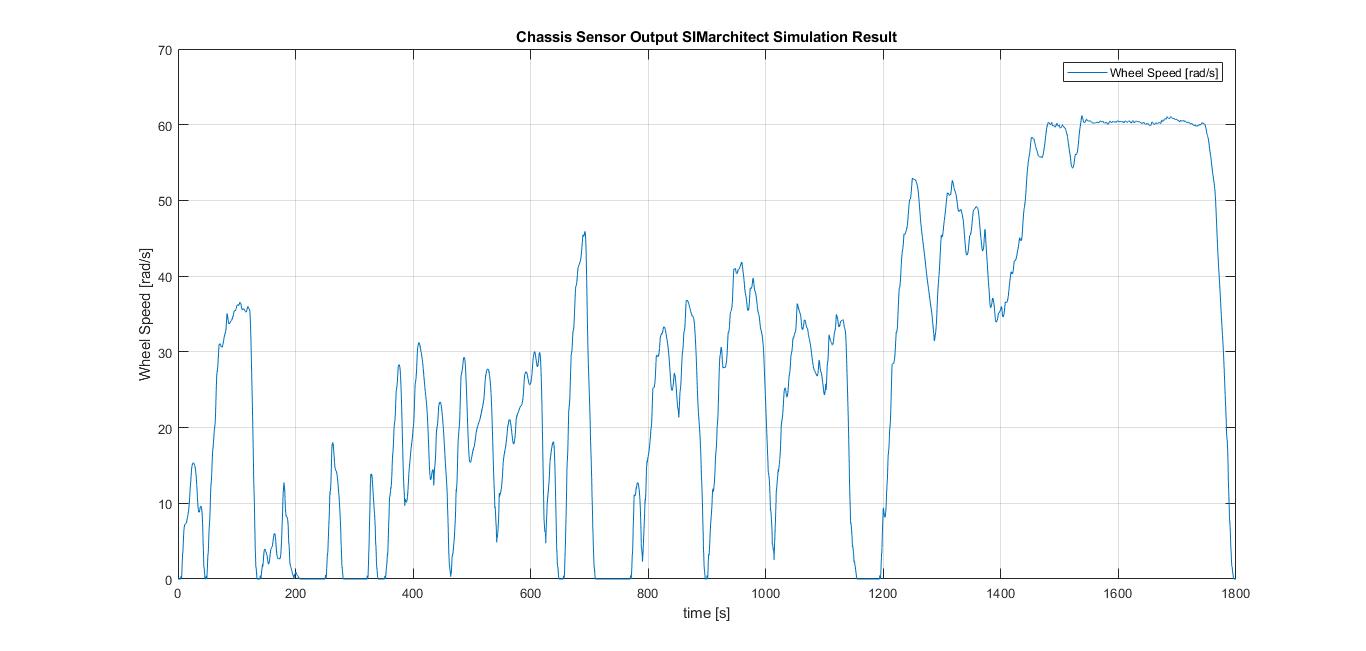

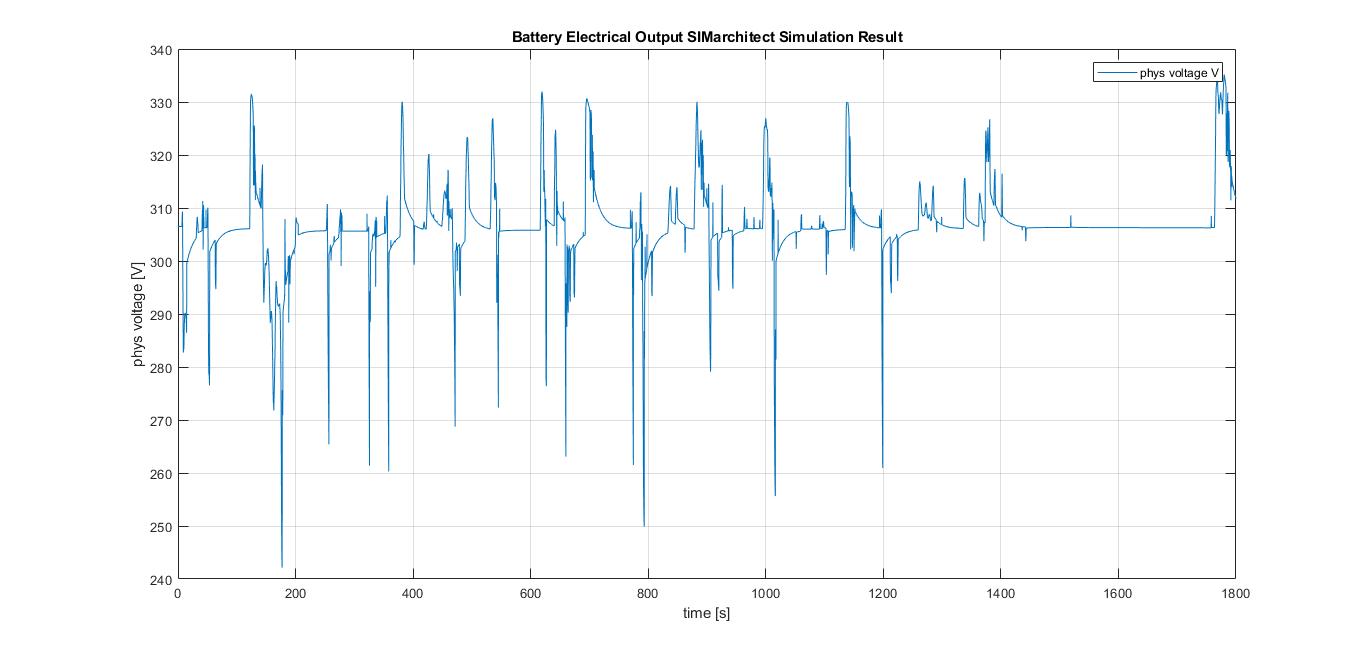

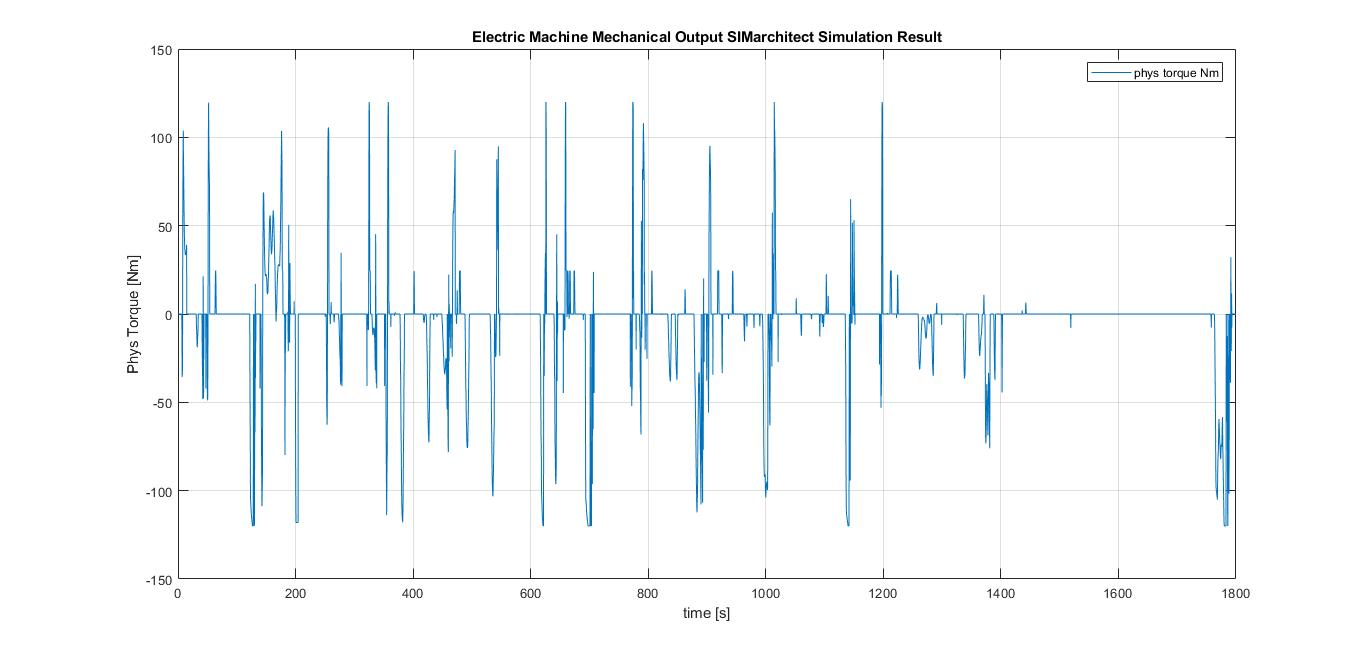

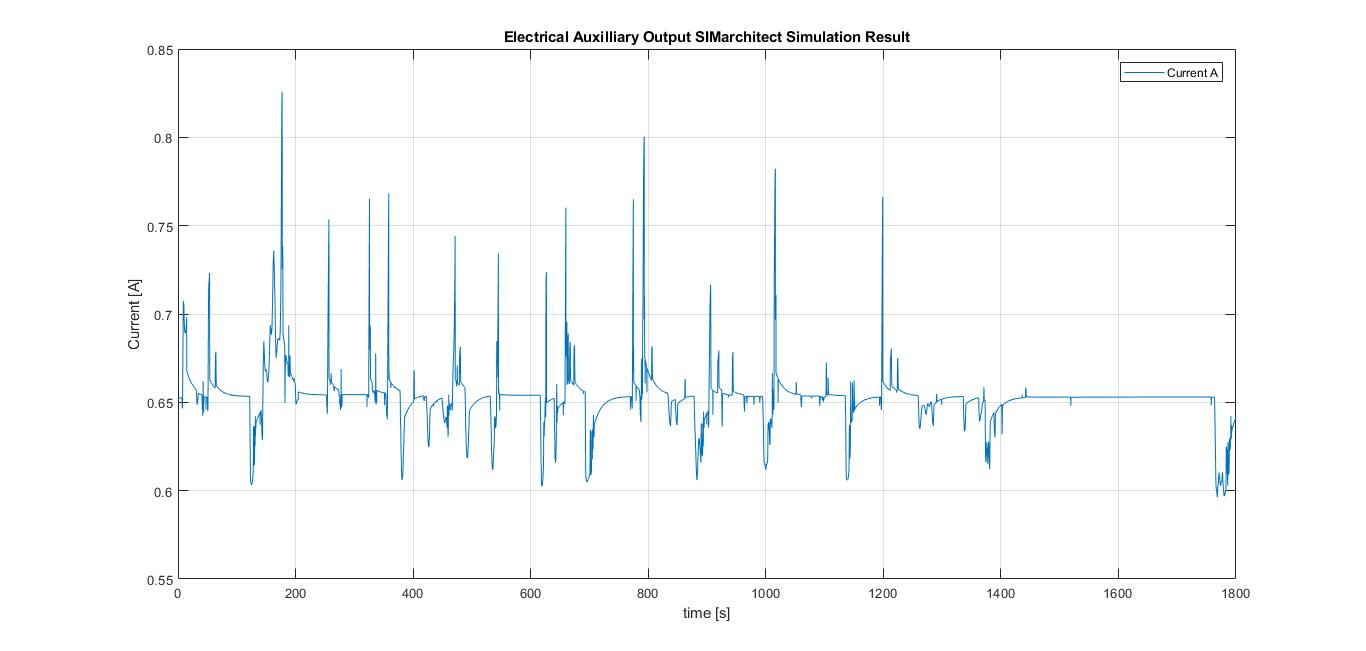

Simulation Result

Use these Simulation Results to do graphical validation.

The simulation results of the parallel hybrid vehicle are as follows:

| Module | Result |

|---|---|

| Internal Combustion Engine | |

| Clutch | |

| Mechanical connection | |

| Transmission | |

| Final gear | |

| Chassis | |

| Battery | |

| Electric Machine | |

| Electrical Auxiliary system |