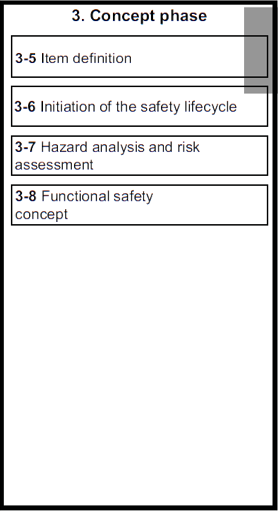

3. Concept Phase

The concept phase of ISO26262 consists of four clauses and creates the right preperation for the actual product development.

First, the item is described in the Item Definition. The Item Definition describes the Item, external dependencies and interactions with its environment and, possibly, other items. It is encouraged to keep any already existing information at hand when creating the Item Definition, like the product idea, sketches, relevant patents, documentation of predecessors, etc.

Provides a detailed description of the safety related item with regards to its functionality, interfaces, environmental conditions, legal requirements, hazards and more. The preliminary architecture is usually a part of the Item Definition, or the Item Definition contains a reference to it.

3-6 Initiation of the Safety Lifecycle

Here the distinction is made whether it concerns either the new development or a modification of an existing item. If it concerns a modification then also the necessary safety lifecycle activities shall be defined.

3-7 Hazard analysis and Risk assessment

Exposes all hazards and detemines the risk involved. A safety goal (SG) with an assigned ASIL level is the result of performing a HARA.

The Functional Safety Concept encompasses functional, implementation independent requirements on the safety of the Item. It refines the Safety Goals by defining the Safety Goals attributes and it establishes a link between the functional safety requirements and the preliminary architecture.

Hints and Tips:

Item Definition

Reuse of an item/system/array of systems can be done when the item definition of both the old and new are the same. This leads only to the adaptation of the work products. Do not include other safety mechanisms in the block diagram of the item definition.

Initiation of the Safety Lifecycle

Try to perform an FMEA for every step in the safety lifecycle. Anticipate on what can go wrong to prevent work from being redone.

Hazard analysis and Risk assessment

When making a HARA, it's a good idea to immediately assign safety goals to hazards which have an ASIL classification. This makes the HARA a bit more complex but has the advantage that it keeps all the info together, enhancing traceability and readability. To make well-supported choices it's possible to search for statistical data on [www.destatis.de]. This website contains statistical information on a wide range of topics, one of which is traffic incidents. When performing the HARA, also take into account smoke and fire. If smoke and fire appears to be a safety hazard, it has to be taken into account as a safety topic.

Functional Safety Concept

When it concerns the development of a new item, it would be much faster to model the functional safety concept by using a regular whiteboard and marker. Because in this stage the concept is subject to frequent change, there's the advantage of a quick wipe and redraw. Make pictures for documentation purposes and refactor the functional safety concept when the concept is finished. Refactor it using a more formal method like modelling in Enterprise Architect.